ACTIVITIES AND CAPABILITIES

TRIME, C.A., through its Manufacturing Organization, has proven experience and has the most qualified human resources..

In addition, we have cutting-edge technology as well as equipment, machinery, tools and facilities of the highest quality.

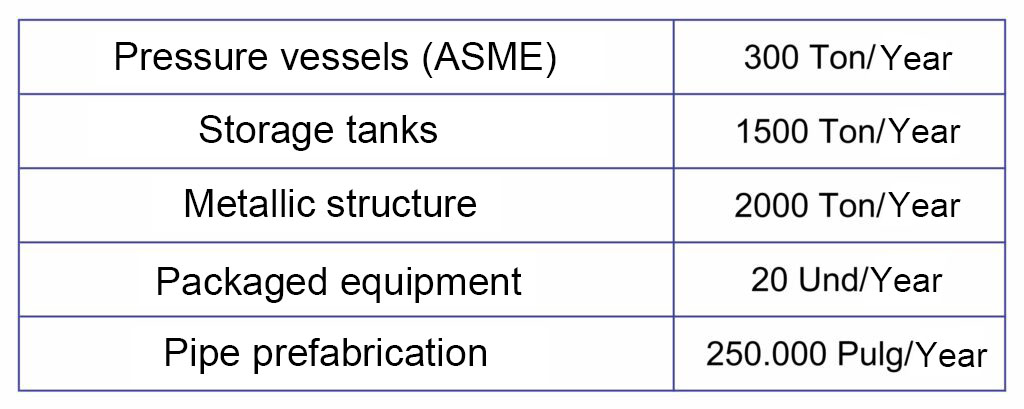

We have the capacity that characterizes us as leaders in the production of the following products:

DESIGNS AND CERTIFICATES

In order to guarantee the structural stability of new designs, repairs and modifications to existing equipment, our company has highly qualified and trained personnel.

Design - Specialized Software

SAP

Specialized program for the calculation of structures, plates, shells and sheets, with availability of finite element analysis for different combinations of loads.

CODEWARE

Program for calculation of pressure vessels both by section VIII divisions 1 and 2, for "U", "UM", "U2", "R" stamps, as well as heat exchangers with strict compliance with the re-written UHT chapter.

TEKLA

Software for design and modeling of metallic structures in 3D, which in conjunction with our CNC equipment (Peddinhaus), bring design times as well as manufacturing times and errors to a minimum thus expediting the assembly of temporary or permanent structures for expedited application solutions.

AUTOCAD

Universal design tool, channel par excellence for the communication of ideas between specialized technicians, as well as generator of execution documents.

Certificate

WORKS EXECUTED

TECHNOLOGY

Oil and Gas Separation Technology

The TRIME, C.A. Group has extensive experience in manufacturing pressure vessels for gas separation and crude oil treatment processes.

We also have strategic alliances with companies at the forefront of these technologies, these include:

- Amistco.

- Taylor Forge

- Delta Dps.

This allows us to offer solutions and process engineering in different levels of oil and gas production, both UPSTREAM and DOWNSTREAM, such as

- Biphasic gas separation

- Three-phase oil/gas/water separation

- Crude oil treatment

- Removal of liquids

Equipment Offered

Gas Separation

- Coalescing gas Filters

They are used to remove solids and liquids with an efficiency of 99.99% for particles larger than 0.3 microns, through filtering elements.

- Absolute separators

They combine filtering elements with cyclone-type internals, which increase maintenance time and handle higher gas flows. They operate at 100% for particles larger than 0.3 microns.

- Two-phase Vertical separator

Used to optimize space, they remove solids and liquids with 100% efficiency for particles larger than 8 microns. They are used with cyclonic, vane, or mesh type interns.

- Two-phase Horizontal separator

Used when large quantities of liquids are expected. They remove solid and liquids particles larger than 8 microns with 100% efficiency. They are used with cyclonic, vane, or mesh type.

Oil and Gas Separation

- Vertical three-phase oil/gas/water separator

They use retention time for the separation of oil, water and gas.

- Horizontal three-phase oil/gas/water separator

They use retention time for the separation of oil, water and gas.

- Sand separator

Used to remove sand from the crude flow. It is equipped for easy transportation and installation.

- Slug Catcher Scrubbers

Its function is to collect the condensed liquid along the gas lines, restoring the gas/liquid ratio to optimal levels

Crude oil treatment

- Vertical Treatment

They use heat and retention time to separate emulsions in the crude oil.

- Vertical Treatment

They use heat and retention time to separate emulsions in the crude oil.

- Stabilizer

They reduce the RVP of oil in storage and transport

Liquid removal

- Vent Scrubber

It separates the remaining drops from the liquid, usually used before sending the gas to the flare.

- Water skimer

It is designed to provide long residence time with coalescent plates to separate the small drops of crude oil from the water.

- Blowcase

They are used to collect liquid at low

- Sump Tank

They are atmospheric tanks that produce water free of crude oil.

Industrial

Pressure Vessels

- ASME Stamps (U) (U2) (R) (S) (PP)

- Rolling of 2 ½¨, with numerical control calender.

- Experience in carbon steel and special materials (316 stainless, duplex).

- Manufacturing of high thickness tanks (4¨), diameters (4,5m) and lengths (30m).

- Forming of torispherical heads up to 5 m diameter.

- Supply and installation of internals for oil and gas processes.

Storage Tanks

- Manufacture of atmospheric storage tanks according to API standards, conical roofs, domes, floating.

- Manufacture of bolted tanks.

- Complete processes of sand blasting, painting and/or coating.

- Etank design software.

Metal Structures

- Heavy, medium and light structure manufacturing, bolted and/or welded structures, tubular structures, ducting.

- Peddinghaus bdl 1250/3 numerical control for drilling and cutting profiles, with direct interface to design software (tekla structure).

- Sheet cutting with ESAB SABRE DX numerical control pantograph.

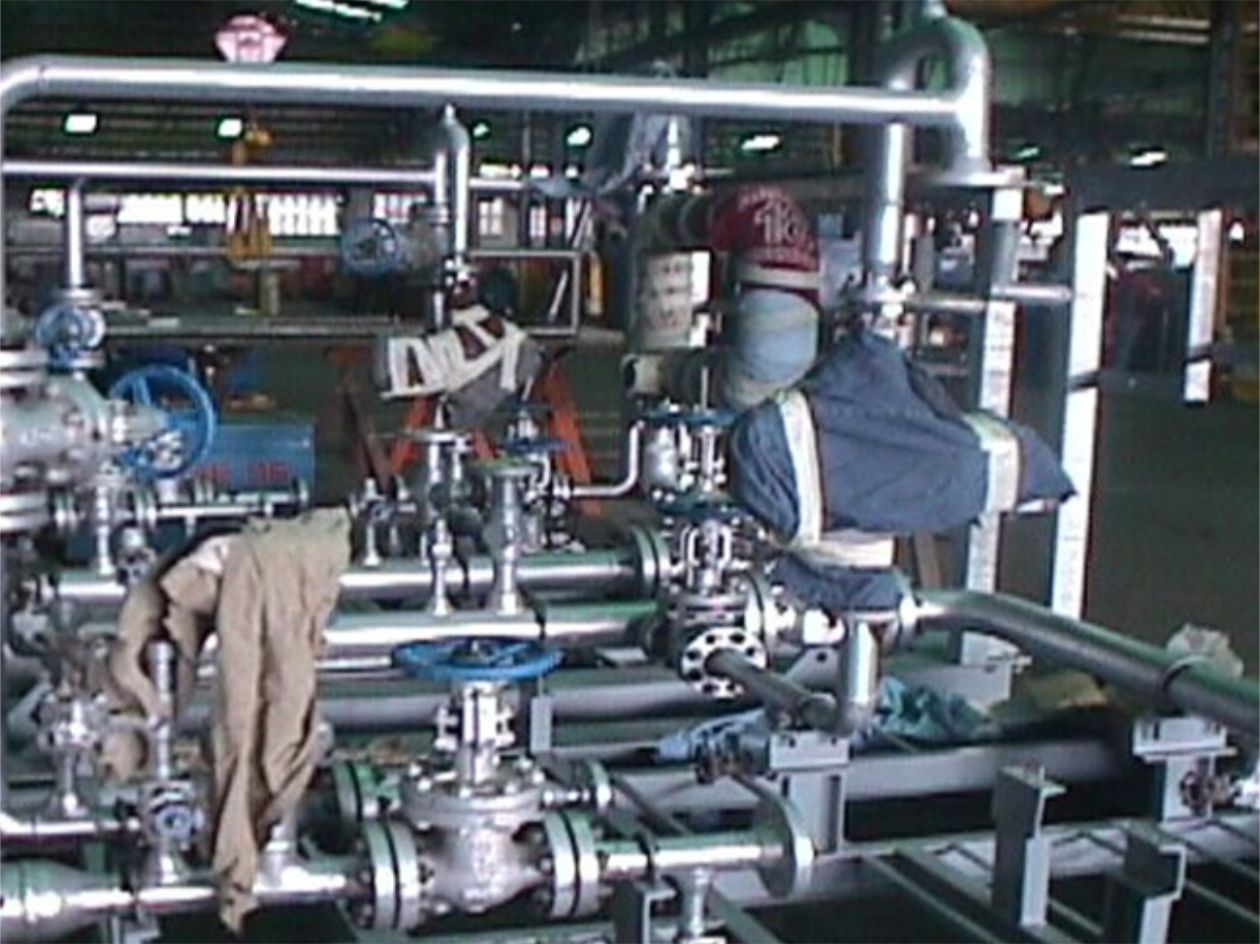

Paquetized Equipments

- Manufacture of multiport valve skids for oil and gas handling.

- Supply and installation of valves and instrumentation.

- Modular gas treatment and sampling systems.

Pipes Prefabrication

- Experience in pipe prefabrication for various types of industrial plants.

- Pre-fabrication of expansion joints.

- Experience in pre-fabrication of high thickness piping.

- Pre-fabrication of pipes in carbon, stainless and alloy steel.

Heat Exchangers

- Manufacture and repair of shell and tube heat exchangers, fan coils, heaters.

- Automatic orbital TIG welding machine for the union of tubing and plate.

- Tube expansion machine.

- Mechanical design with Compress software under ASME and theme standards.